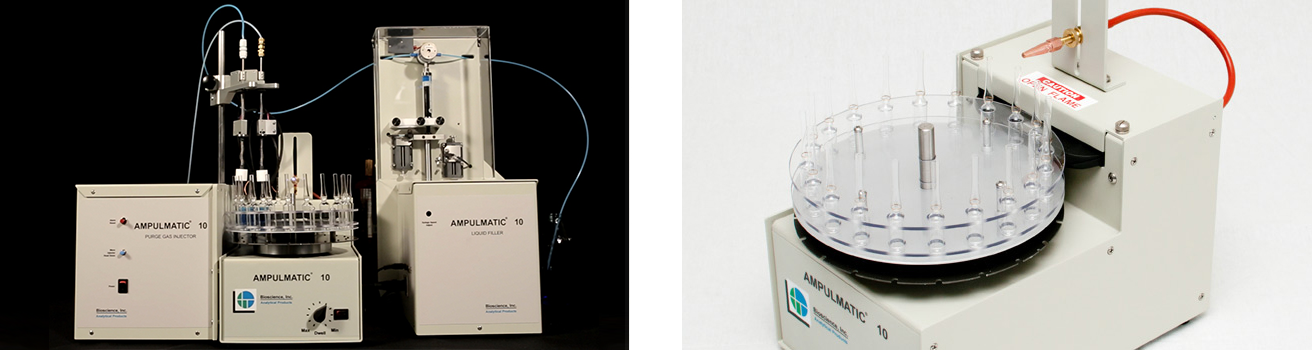

Ampulmatic-10 Bench Scale Ampule Filler/Sealer

Monera's Ampulmatic-10® Ampule Sealer is the ultimate solution to the problems faced by organizations and institutions that need to seal ampules on a bench or pilot scale.

Get Yours Today

Generally made of glass, ampules need to be sealed after being filled with liquid/gas to make sure that they remain protected from air and other contaminants.

Although they can be filled manually, the process can be quite labor-intensive. It can even be inconsistent, inefficient and expensive, especially as the number of ampules to be sealed increases. The AMPULMATIC-10 automates the process for small or moderate amounts of ampules, allowing users to enjoy a dramatic increase in ease, speed and consistency of ampule sealing – all for a modest investment.

As our Ampule Sealing machine is available at a competitive price, you can buy it even if you are on a low budget. Besides consistency, speed, and accuracy, some other benefits of this state-of-the-art machine are that it is easy to clean and calls for minimal maintenance. When combined with the optional inert gas injector and/or the optional liquid filler, it works as an Ampule Filling Machine. Therefore, it can be used for both filling as well as sealing ampules at a lesser expense than the manual process.

AMPULMATIC-10 Features:

- Easy setup

- Fully automatic operation

- Proven seal consistency at the bench and pilot scale

- Inexpensive, efficient operation (Up to 900 ampules per hour)

- Optional Purge Gas Injector module

- Optional Liquid Filler module

- Easily adjustable ampule dwell time

- Ampule sizes from 1-50 ml

- Universal 100-240v power supply

Resources

)

Case Study

MIDI, Inc. Case Study

)

Datasheet

Ampulmatic®-10 Ampule Sealer

)

White Paper

Ampule Sealing Methods

)